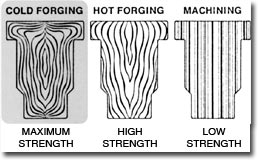

Unbroken grain makes the strongest part possible. Cold formed parts replace traditional hot forged and machined parts with a stronger, net shape part requiring no secondary machining and increasing machine throughput. Cold forming vs. machining saves an average of 49% in material costs alone.

Consider cold forming instead of...

Hot forging

Cold formed parts are stronger, with better metallurgical properties, less costly, net or near net shape, lower scrap, simplified production, and more reliable service performance.

Castings

Cold formed parts are stronger, more reliable and overall less costly, with better dimensional stability and tighter tolerancing.

Powder metal

Cold formed parts are stronger, with higher part integrity, fewer secondary operations, and less costly material.

Machined from bar stock

Cold formed parts are stronger, with more cost-effective use of materials providing lower scrap. A near net shape cold formed part lowers machining time and requires fewer secondary operations.

Weldments and stamping fabrications

Cold formed parts are stronger, production economies, materials savings, more consistent, better metallurgical properties, simplified production, and lowers the cost of design and inspections.

Reinforced plastic / Composites

Cold formed parts are stronger, with less costly materials, more reliable service performance. They have established documentation, greater productivity and a broader service temperature range.