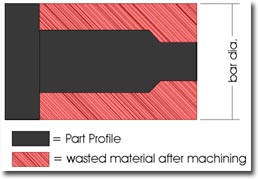

Cold forming replaces hot forged and machined parts with a NET SHAPE cold formed part, requiring no secondary machining and eliminating additional time and cost. Splines can be made on O.D. and I.D.

Ten ways that Cold Forming can help you reduce cost:

- Greater strength to weight ratio

- Less material needed

- Fewer secondary operations

- Eliminate or reduce machining

- Eliminate costly fabrications and assemblies

- Eliminate welding

- Use less expensive materials achieving the same strength

- Quicker print to part startup

- Reduce inspection and testing

- Optimize complete assembly by less components needed

Traceability

- Material heat is designated to steel at time of pouring. This heat I.D. is maintained throughout processing

- Work order & run code are assigned to each heat prior to processing. These assignments allow us to trace material and all production records back to Mill heat of material. Upon customer requests, this number can be formed directly into the part for field traceability.

- Parts shipped to the customer with full traceability to mill heat of material.

Additional Cold Forming Facts

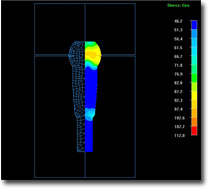

- Yield strength increases: 100% - 300%

- Ultimate tensile strength increases: 30% - 120%

- Hardness increases: 60% - 150%

- Elongation decreases: 20% - 90%

- Reduction of area decreases: 20% - 60%